Description

Product Paramenters

|

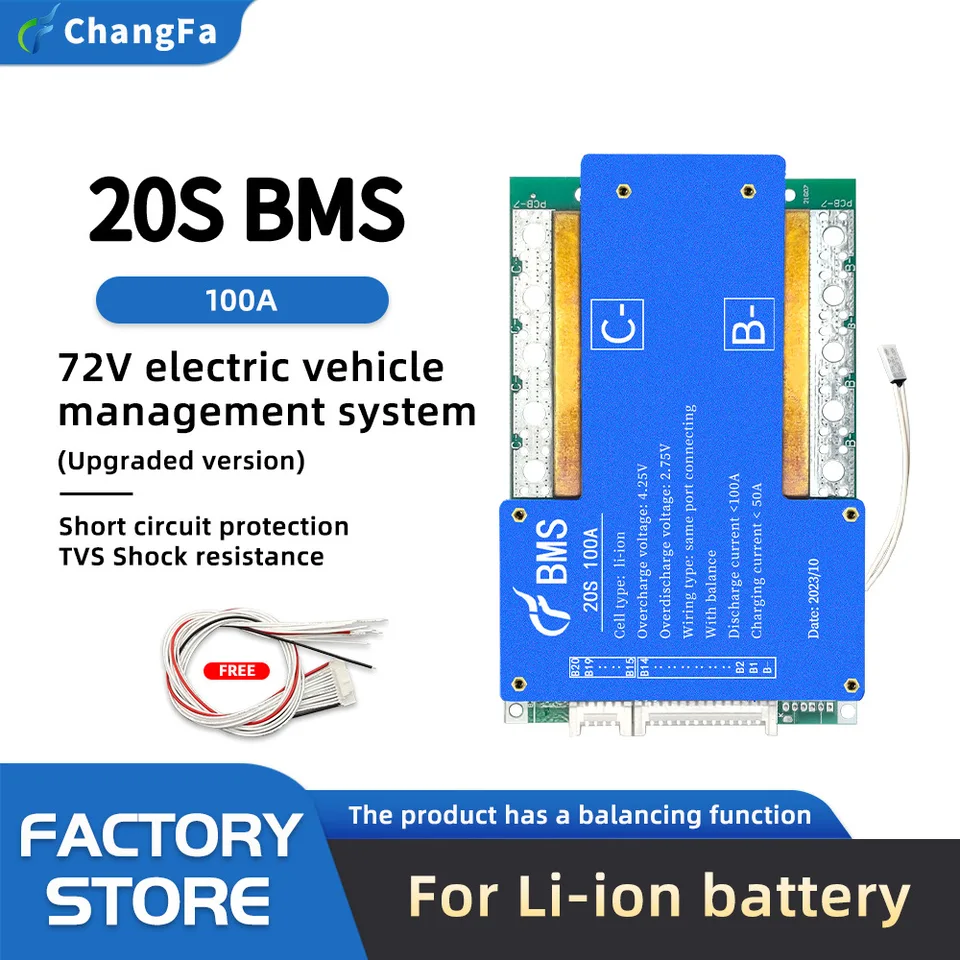

Discharge current(MAX)

|

100A

|

||

|

Charging current

|

≤50A

|

||

|

The main circuit conducts the internal resistance

|

≤15MΩ

|

||

|

Discharge overcurrent protection

|

300A±50A

|

||

|

Overcharge protection

|

Overdischarge voltage protection

|

||

|

Detection voltage

|

4.25±0.025V

|

Detection voltage

|

2.75±0.1V

|

|

Detection delay

|

1000±500MS

|

Detection delay

|

1000±500MS

|

|

Release voltage

|

4.15±0.05V

|

Release voltage

|

3.0±0.1V

|

|

Balance voltage

|

Discharge overcurrent protection

|

||

|

Detection voltage

|

4.15±0.025V

|

Detection voltage

|

50±15MV

|

|

Detection delay

|

100±50MS

|

Detection delay

|

1000±500MS

|

|

balance current

|

42±5MA

|

Overcurrent protection

|

300±50A

|

|

Short circuit protection

|

Temperature protection

|

||

|

Trigger condition

|

External short circuit

|

Charging temperature

|

75°C±2

|

|

Detection delay

|

300US

|

Discharge temperature

|

75°C±2

|

|

Release condition

|

Load disconnect

|

Release condition

|

Restore within operating temperature

|

|

Consumable electricity

|

|||

|

Working power consumption

|

≤35UA

|

||

|

Hibernation over discharge consumes power

|

≤10UA

|

||

|

Operating temperature range

|

-30°C+80°C

|

||

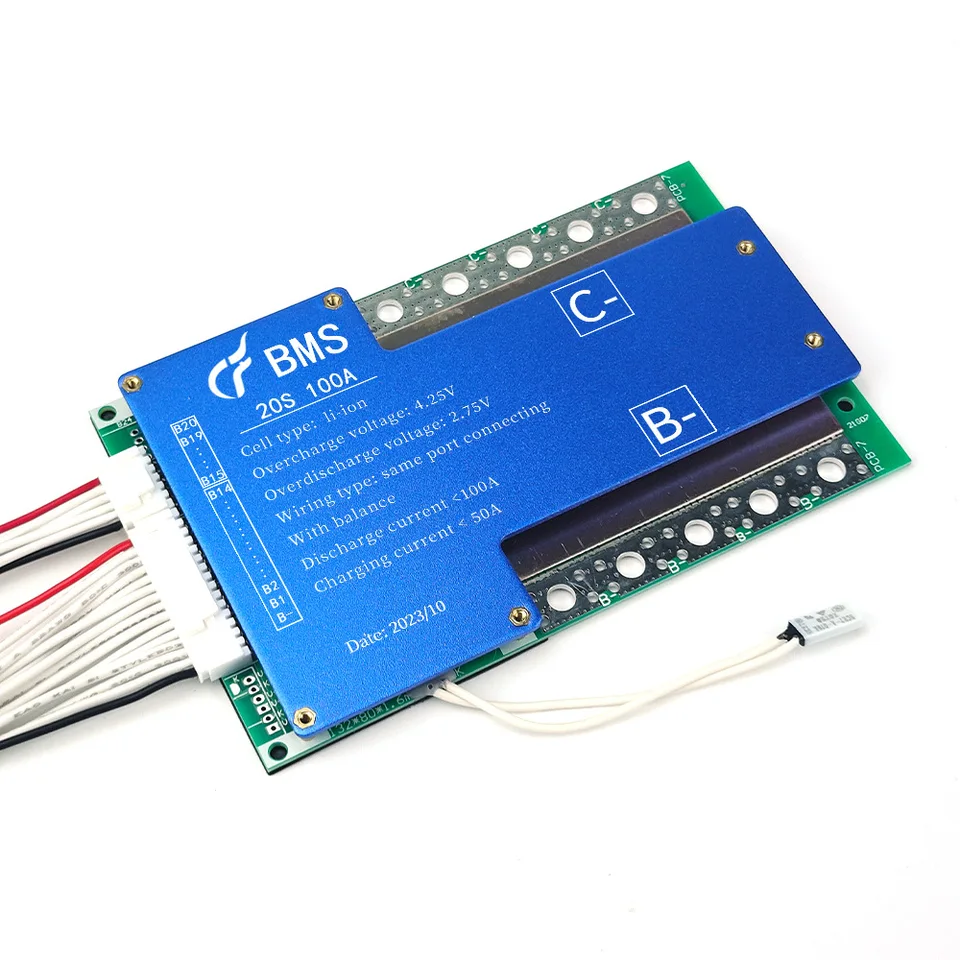

Product Description

CF-SW24S200A-E

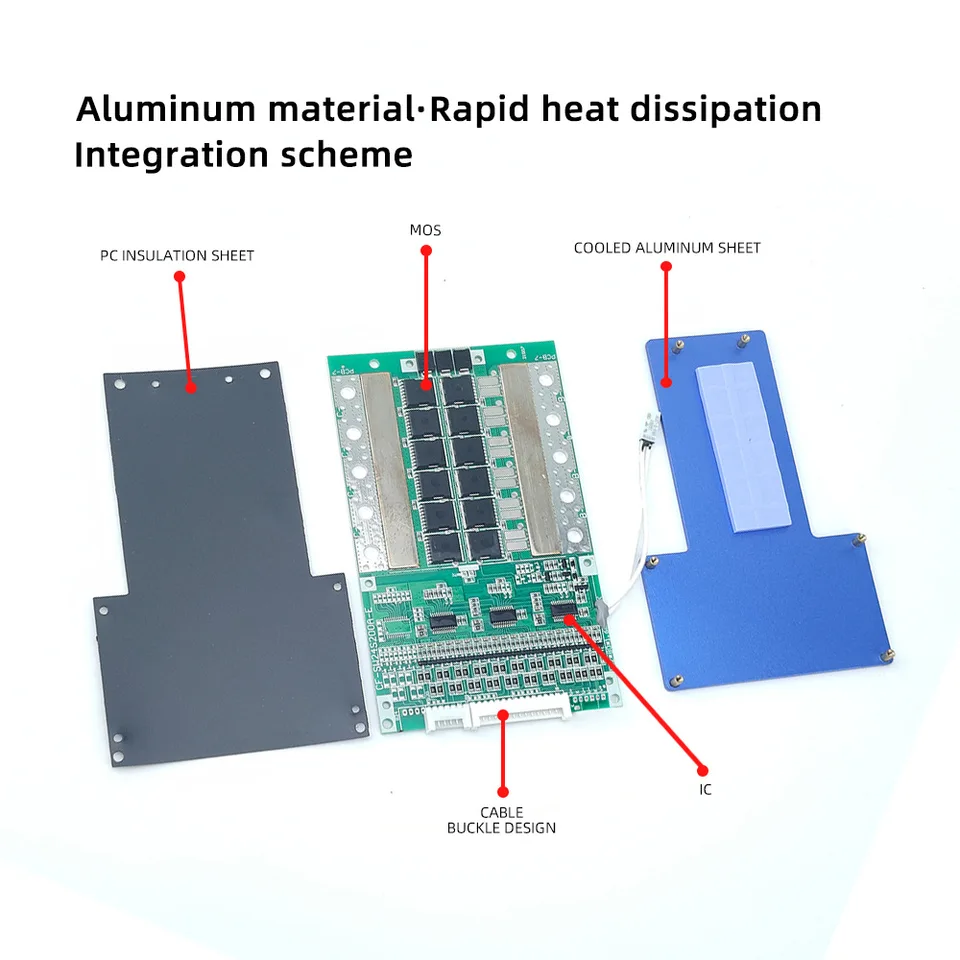

CF-SW24S200A-E is designed by Huizhou Changfa Electronic Technology Co., LTD., specially designed for energy storage power 4-24 series lithium iron phosphate battery pack, outdoor power supply, motor home energy storage, medical battery, electric vehicle power and other products designed protection plate solution. Suitable for lithium ion, lithium polymer, lithium iron phosphate and other different chemical properties of lithium batteries, protection plate bearing capacity, the maximum continuous discharge current up to 100A/150A/200A. (1) 4-24 batteries in series protection (2) charge and discharge protection function (3) Hardware discharge overcurrent, short circuit protection function processing (4) GPS port/weak current switch (5) temperature control protection

Installation Instructions

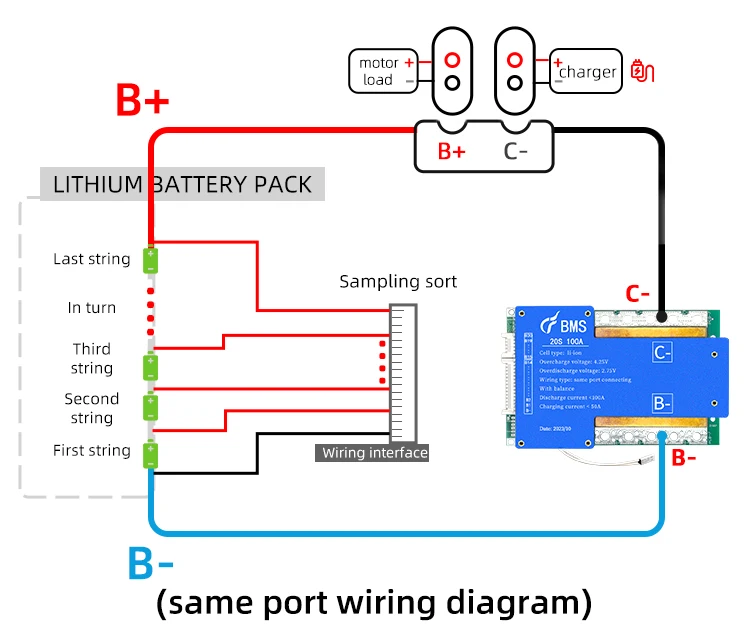

Protection board wiring diagram

The wiring method of different manufacturers is different. Do not insert protection plate in the welding wiring

If only one string is used as an example, the same analogy can be used to connect the protection board with other string numbers

*lmportant note: Different manufacturers different connection, please buy the supporting line of the protection board, do not useother do not belong to the supporting line!! Due to the use of parts do not belong to the usual wiring, if there is a problem,will not accept return and replacement! *

Step 1: Connect cables to the protection board

First connect the B- and C- wires on the protection plate (the split-plate needs to be connected to P, and the same plate C- needs to be charged and discharged, and the wires must be thick). The B- wires should be welded to the total negative electrode B- of the battery, and then connect the bar wires (before connecting the bar wires, be sure to pull the bar wires from the plate).

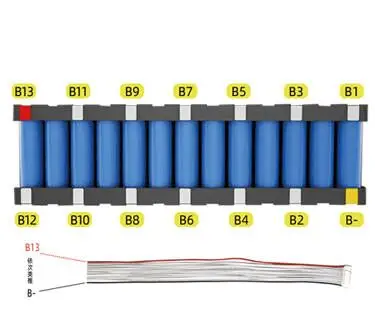

Step 2: Acquisition voltage line welding

Start wiring from the black thin wire at the far right of the row (connected to the total negative terminal of battery B), the second row of wires from the black thin wire to the left of the first thin wire connected to the first series of positive battery (the first battery of the total negative terminal), the third row of wires connected to the second series of positive battery, the fourth row of wires connected to the third series of positive battery… . … In order from right to left, and so on, until the final series of total positive B+.

Step 3: Measure the output voltage

Finally, measure whether the total voltage of the battery and the output voltage of the protection board are equal, equal protection board is working normally.

Factory manufacturing

Reviews

There are no reviews yet.